History

Brick Making in India

History of Brick Making

A brick is a block made of clay burnt in a kiln. It is one of the primary building materials known to mankind. Over time, bricks have appeared, gained prominence, lost importance and then come to the forefront again with various styles of architecture. Burnt bricks were used in ancient Indian, Babylon, Egypt and Roman civilizations. They are still being used as filler materials for framework structures as well as to construct load bearing structures. Down the ages, there have been various interesting historic and cultural references to bricks.

- Bricks find mention in the Bible; the tower of Babel was built with burnt bricks.

- Bricks were predominantly used in the Indus valley civilisation. In fact, the civilisation was first discovered when; ancient bricks being used to build railway ballast came to the notice of a passing archaeologist.

- While the Taj Mahal was built in white marble, it had extensive scaffolding made entirely out of brick, which was pulled down after completion.

Making the Brick

The process of making a brick has not changed much over the centuries or across geographies. Traditionally the main steps followed to make a brick are explained below.

- Material Procurement: The clay is mined and stored in the open. This makes the clay soft and removes unwanted oxides.

- Tempering: This clay is then mixed with water to get the right consistency for moulding. Mixing is done manually with hands and feet. Sometimes and in certain areas, animal driven pug mills are used.

- Moulding: A lump of mix is taken, rolled in sand and slapped into the mould. Initially moulds were made of wood, now metal moulds are used. Sand is used so the brick does not stick to the mould.

- Drying: The mould is emptied onto the drying area, where the bricks are arranged in a herring bone pattern to dry in the sun. Every two days they are turned over to facilitate uniform drying and prevent warping. After two weeks they are ready to be burnt.

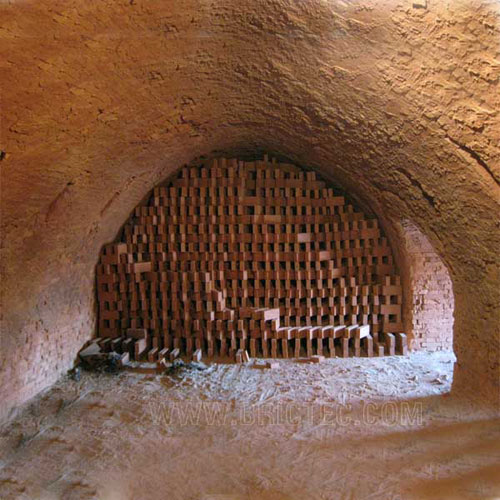

- Firing:The green bricks are arranged in a kiln and insulation is provided with a mud pack. Fire holes left to ignite the kiln are later sealed to keep the heat inside. This is maintained for a week. Firing like other operations also depends on the knowledge and experience of the brick maker.

- Sorting:After the kiln is disassembled, the bricks are sorted according to colour. Colour is an indication of the level of burning. Over burnt bricks are used for paving or covering the kiln while slightly under burnt bricks are used for building inner walls or burnt once again in the next kiln.

Sorting

Drying

Moulding

Tempering

Though the overall method remains the same, there are certain regional variations considering the local soil and climatic conditions. In different areas, different soil types are used with respect to local situation. The three general approaches for firing bricks include using a massive fire, a massive volume and insulation. In Africa and South America, a massive fire using wood fuel is built, and insulated with mud or grass. In India and Mexico, they fire large volumes together and the volume itself acts as an insulator to prevent escape of heat. Fuel ranges from wood to coal to biomass to even garbage and trash in the absence of others.

Brick Kilns

Brick Kilns can be classified as intermittent and continuous. Clamps, Scotch, Scove and Downdraft kilns are intermittent while the Bull Trench (BTK), Hoffman, Zig-zag, Tunnel and Vertical Shaft Brick Kilns (VSBK) are continuous. The continuous kilns are more efficient as they have heat recovery features from both the heat in fired bricks and flue gases unlike the intermittent ones.

Intermittent Kilns

The oldest kiln is the clamp.Invented in 4000 BCE, these are still very common in India. Clamps are temporary constructions made of green bricks or clinker. The clinker can be reused while the green bricks are sold. A slight variation is the Scove with a pile of dried bricks with tunnels at the bottom allowing heat from fires to pass through and upward in the pile of bricks. It is plastered with mud (scoved) to insulate it. Certain brick makers use permanent clamps made of refractory bricks. Two basic variations of kilns are the updraft and the downdraft kilns, named after the direction of heat movement. The updraft ones or Scotchhave flues running through the floor of the kiln with spaces between the stacks of bricks to allow heat to circulate, while the top is covered for insulating the kiln. The downdraft ones are circular with the flue running from the floor to the chimney stack. The hot air is then directed downwards from the dome through the stacks of bricks.

Continuous Kilns

Continuous Kilns can be based either on the principle of moving fire or on moving ware. The Hoffman, BTK and Zig-zag work on the principle of moving fire. In the Tunnel and VSBK, the firing zone remains constant while the bricks move.

Hoffman’s kilns are continuous domed kilns invented in Germany. They have a permanent arched masonry and tall chimney. The circular arched tunnel surrounding the chimney has various chambers where green bricks are placed and the fuel is added via vents in the roof.

The Bull Trench Kiln (BTK), which is very popular in the Indian sub continent, is an arch-less modification of the Hoffman’s kiln. It is circular or elliptical in shape. Bricks to be fired are arranged in a trench and tall movable metal chimneys are placed on the brick setting. They are moved as the firing progresses. There are also modifications of the BTK which have a permanent fixed chimney.

The Habla Zig-Zag Kiln, is also a German invention. It is an automated tunnel kiln. This one has a fire zone moving through a stack of stationary bricks. The fire moves with the help of an axial fan. The bricks are arranged such that hot flue gases move between them in a zig-zag manner resulting in better heat utilisation and energy efficiency.

Another kind of continuous kiln is the Tunnel Kiln. The principle is to move green bricks through a stationary fire. It is energy intensive and generally used in developed countries. It is essentially a 50-100 ft long rectangular chamber lined with high quality refractory bricks. The bricks are loaded from one end in a car at a predetermined pattern. After a fixed interval of time, depending on the firing cycle, a car is pushed from one end, simultaneously taking one car out from the other end of the tunnel.

The Vertical Shaft Brick Kiln (VSBK) , is a Chinese technology based on the traditional updraft intermittent kiln. The kiln consists of one or two shafts in a rectangular structure insulated with agriculture residue and clay. The shaft is loaded from the top in a pre determined pattern. After being fired in the shaft they are removed batch wise from the bottom via an unloading tunnel. It is well suited to the context of the South Asian brick sector.

VSBK

Bull's Trench Kiln

Chinese Hoffman Kiln

Clamp